AUTOMATIC CAR WASH TUNNEL

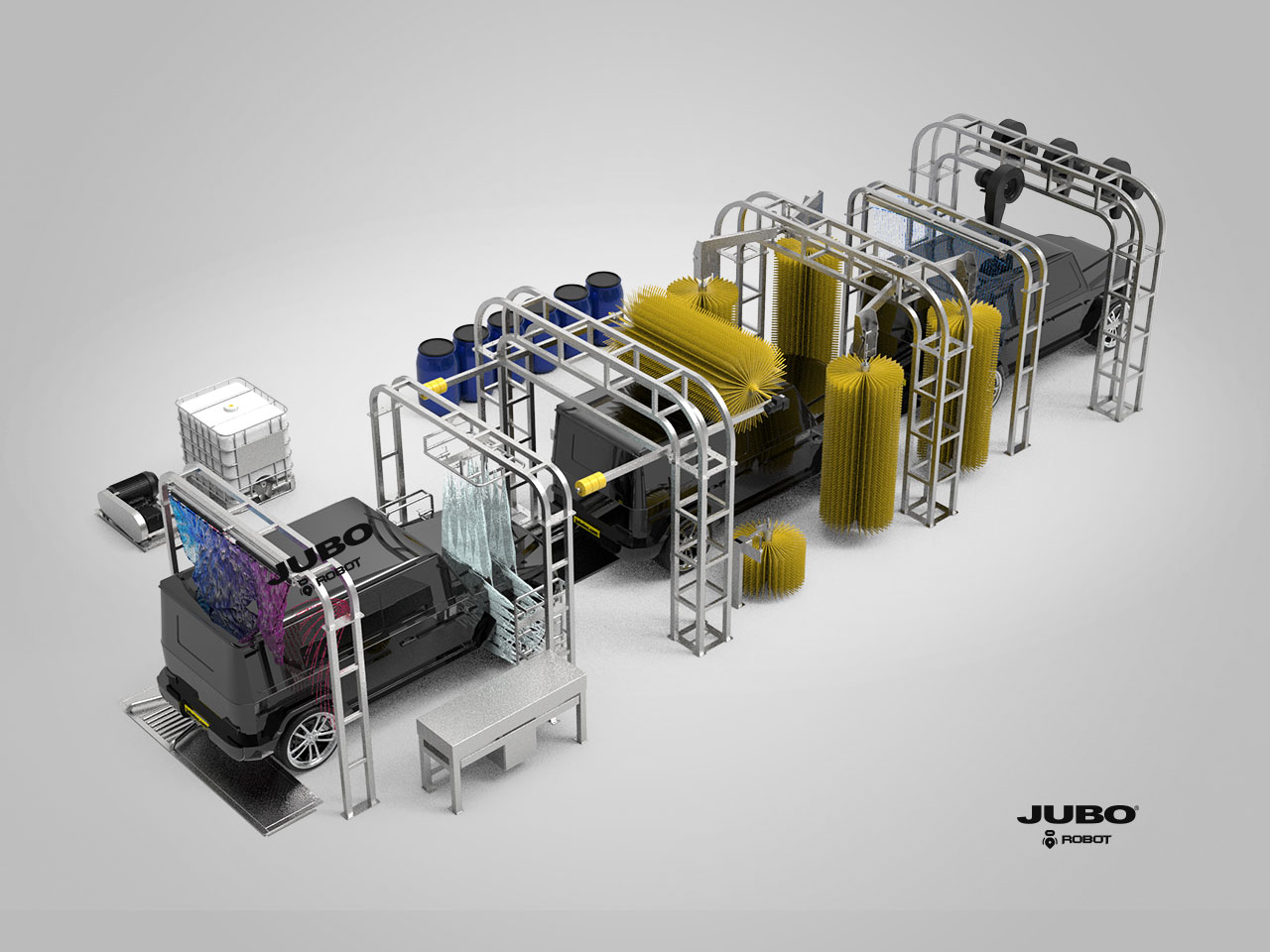

CONVEYOR WASH TUNNEL - ECO JUBO

Model: ECO, Type: Tunnel automatic friction express

Hotwax, Rainx!!! you need JUBO foamfall for your absolute glorious wash tunnel!

Wash Tunnel, automatic conveyorized car wash with steel or plastic belt conveyor.

JUBO ECO WASH TUNNEL FULL AUTOMATIC CAR WASH MACHINE boost your revenue growth!

Excellent king

Flexible

High pressure water

Automatic car wash tunnel with lavafoam

Wash tunnel key features

Automatic wash tunnel with standard 9 brushes allow 3 cars washing in tunnel Synchronously, fastest 1 minute to finish all washing steps per car wash. 0.1KWH power and 200L for each wash means high return on investment, capacity of wash 1000+ cars per day non-stop for WASH TUNNEL AUTOMATIC CAR WASH MACHINE.

JUBO understand what you cares, invest funds always pursuing high return investment. Car wash tunnel is the king among all automatic car wash system.

- Customers love fancy washing tunnel with LED illuminations.

- Fastest 1min automatic car wash always attract customers back and favor again.

- Cleaness by #softtouch fabric brushes satisfying customers proudly.

- Customers happy with fast throughput and no more boring wait long queue, step on the conveyor, wash tunnel ECO do the rest automatically 'cause it washes 3 cars in same time.

- Investor happy with car wash tunnel 'cause it bringing revenue every second.

- Reliable wash tunnel system due the simplest mechanic design with simplest movements.

- Flexible modular wash tunnel arches can be added or removed or put in any position and order due various requirements.

Wash tunnel functional parts

Hot dip galvanized steel conveyor x 1pcs

Durable reliable used in anywhere, it can be put outside open area without roofing or can be put inside a room with shelter, exposuable to the sunshine, rain or even tougher conditions.

Lava-foam / Hot-wax x 1pcs

Lava arch can be used for high foam in the entrance or hydrophobic clear wax or hot wax or other solvent chemicals due stainless steel 304 material used on the applicator. Lavafoam / Foamfall / Waterfall / Cascade for autumatic tunnel car wash.

Underbody chassis wash unit x 1pcs

With high pressure water support the sectorized nozzle array made a high pressure blade to clean out the grimes underbody, side wash nozzles can spray to both sides and wheels.

High-pressure oscillating water x 3pcs

Oscillating water arrays on top and both sides to flushing grimes on the car top and sides, rinsing out the dirties, the working pressure is 100+bar.

Top Brush x 1pcs

Top brush for car roofing area cleaning. Height set to permit 2100mm vehicle height clearance, if 2350mm or higher vehicles need to pass through please raise customization requirements to JUBO sales.

Brushes fabric or automatic car wash tunnel, quality-oriented fabric brushes lifespan 400,000~600,000 car wash

Wheelbrush x 2pcs

With water engaged together with rotary brushes. Flush out the dirties on wheels. moving synchronously to the conveyor.

Side brushes x 2pcs

Side brushes cleaning the low profile side area where is always with heavy grime brought by wheels or rain.

Vertical brushes x 4pcs

The lifted arm is able to deal with highest 2350mm vehicles fixed on a stable gantry with nozzle arrays spraying to the brushes, the front 2 brushes array close and apart to wash the front area while the rear 2 brushes array closed and apart to wash the back area and friction spinning 4pcs of brushes wash around the car. cleanness perfect!

RainWax x 1pcs

RainWax applied before the dryer blower with hydrophobic products, optional 3 or 5 rain pipes casually be used for various chemicals due customers requirements and more revenue washing packages.

Dryers x 4pcs (side blower optional)

Standard with top 4 dryers, normally 1pcs in back and rest front or 4pcs in a line, any requirements could be accepted due flexible modular settings.

the side dryer blade is optional for car side drying.

Wash tunnel ECO advantages

- fastest wash speed

- no waiting queue, no line

- led illuminated foamfall

- clean result assurance

- satisification both by customers and owners

- stable tested Schneider components

- 1000+ car wash per day load capacity

- high-end solution

- pressurized oscilating blaster

- make car wash entertainment & sparkling glorious experience

Wash tunnel installation dimensions

L x W x H = L16000 x W4600 x H 3600mm

Modular structure simple design and sophisticated techonology targeting for high-end urban-style satisfied express tunnel car wash buisiness.

Wash tunnel with hot dip galvanized steel conveyor

Wash tunnel with plastic dual belt conveyor

Wash tunnel with hot dip galvanized steel with glass house, glass prepared by customers.

JUBO WASH TUNNEL, Automatic car wash system, Conveyorized car wash system, Brush touch vehicle wash system, with splendid turnover, Super-Fast, Excellent wash result features, combined with functions of HP Chassis wash & HP Rinse arc, Wheel brushes, Side brushes, Top brush, Vertical brushes, Foamfall, Tri-color foam, Soap Arc, Hot Wax Arc, Spotless Arc, Dryer Arc, etc.

Standard configured by steel conveyor, plastic belt conveyor is an high-end option available.

Automatic car wash system, Conveyorized car wash system, Brush touch vehicle wash system, with Splendid turnover, Super-Fast, Excellent wash result features, combined with functions of HP Chassis wash & HP Rinse arc, Wheel brushes, Side brushes, Top brush, Vertical brushes, Lava-Foam, Tri-color foam, Soap Arc, Hot Wax Arc, Spotless Arc, Dryer Arc, etc.

Flat dual plastic conveyor for wash tunnel system.

Easy entry, Flat, Silent, Self-clean, Self-lubricant wash tunnel conveyor.

Specifications

| Electricity and power supply | 3PHASE 380V 50HZ 65kW |

|---|---|

| Electrical system | French Schneider |

| Min install size | L16000 x W4600 x H 3600mm |

| Max car size | L16000 x W2600 x H2350mm |

| Material | Hot dipped galvanized steel, Stainless steel 304 |

| Water pressure | 100~130Bar |

| Dryer | 5.5kW x 4 |

| Conveyor | Steel conveyor + VFD, Flat plastic belt conveyor + VFD (optional) |

| Speed | 1-3minutes/car, adjustable |

| Chemical | 0.02~0.08L/car, adjustable |

| Wash cycle | Lavafoam Wheelbrush HP Chassis & side wash Top brush Side brushes Vertical brushes RainX Hot Wax(Optional) Dryer Polishing brushes(optional) |

Deployment

Deployed for Chain-business Wash Stations, City Center Wash fleet, outdoor wash stations or near to fuel stations, ideal to make coffee and super-market to enhance revenue, several self-serve wash bays and single automatic tunnel car wash system will be a good idea to work together. Steel frame is necessary to support the components.

Application

- Mini

- Sedan

- SUV

- MPV

- Pickup-Truck

Customization

JUBO understand the importance to make a unique special powerful wash tunnel required sincerely from the market, and it is absolutely accepted.

Here is the simple sample to inspire your intelligence, >>>download the drawing, print it out and feedback with customized hand drawing to sales team by email moc.cniobuj@ofni

Frequently asked question FAQ

How many cars can the wash tunnel eco wash per day?

What power consumption for the automatic car wash tunnel eco?

What if the front car stop in the exit and doesn't want to go out the conveyor?

What size of room should i prepare to install the automatic car wash tunnel?

Can i customize the wash tunnel?

Screen hint, neutral, wheel, brake,Tyre chemical,

Lavafoam,

Wheelbrush,

HP Chassis & side wash,

Top brush,

Side brushes,

Vertical brushes,

RainX,

Hot Wax,RO pressure oscillating rinse,

Dryer,Mitter curtain,

Polishing brushes.

Can put arch in any position you need.Click to download the drawing

Plastic belt conveyor for wash tunnel

Catalog